|

LUMIAURAT

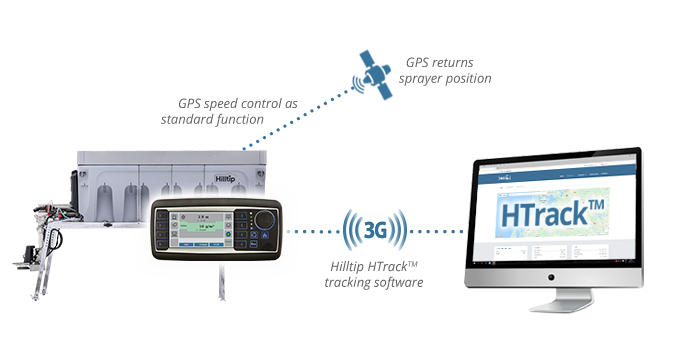

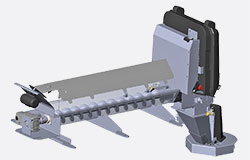

Nivelaura avolava-autoille SnowStriker™ 1650-3200 VP/VMP Alueaura avolava-autoille SnowStriker™ 1650-3000 SP/SMP Levenevä lumiaura avolava-autoille SnowStriker™ 18-26 SFP Nivelaura UTV:lle SnowStriker™ 1450-2600 VUTV Alueaura UTV:lle SnowStriker™ 1450-2600 LS/SUTV Nivelaura traktoreille SnowStriker™ 1450-3200 VTR/VMT Alueaura traktoreille SnowStriker™ 1450-3000 STR/SMT Zoom-aura traktoreille SnowStriker™ SFT Flex Alueaura kuorma-autoille SnowStriker™ 2600-3200 SML/VML SEURANTAJÄRJESTELMÄHTrack™ Levittimen verkkoseurantaohjelmisto |

HIEKOITTIMET

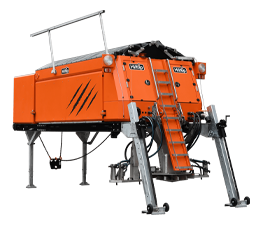

Takalaitalevitin IceStriker™ 120-300 Poly Teräshiekoitin IceStriker™ 380 Stainless Steel Monitoimilevitin avolava-autoille IceStriker™ 550-1250 Poly Lautashiekoitin traktoreille IceStriker™ 400SS TR Stainless Steel Monitoimilevitin traktoreille IceStriker™ 600-1450 TR Poly Monitoimilevitin kuorma-autoille IceStriker™ 1600-2600 Poly Sirotin kuorma-autoille IceStriker™ 3000-7000 Poly Sirotin kuorma-autoille IceStriker™ LION 6-12 Stainless Steel Sirotin kuorma-autoille IceStriker™ TWIN 2400-3000 Hinattavat levittimet IceStriker™ & SprayStriker™ Hiekoituskauha IceStriker™ 220-500 DSB |

NESTERATKAISUJA

Suolaliuoslevitin kuorma-autoon SprayStriker™ 3000-18000 Suolaliuoslevitin avolava-autoille SprayStriker™ 500-2000 Suolaliuoslevitin traktoreille & UTV:lle SprayStriker™ 250TR & 350UTV Suolaliuossekoitin BrineMixx™ 500-3000 DESINFIOINTI & PÖLYNTORJUNTADisinfection Sprayer SprayStriker™ 500-2000 Disinfection Sprayer M-series SprayStriker™ 130-280M Pölynsidontatykki SprayStriker™ HT 45 LANNOITTIMETTeräslannoitin IceStriker™ 380 Stainless Steel |

HARJAKONEET

Lamelliharja SweepAway™ 150-300 cm Pyörivä Harjalaite SweepAway™ 150-220 cm Pyörivä Harjalaite SweepAway™ 310 cm PAINEPESURITHinattava kuumavesipesuri TowJet-it™ 800 Painepesuri Jet-it™ 350-1000 Hydraulinen Korkeapainepesuri Jet-it™ 500-1600 RIKKARUOHONTORJUNTARikkaruohontorjuntalaite WeedStriker™ 350-500 l                                      |